|

|||||||

|

Serious Vought Problems, 1958 - 1969

On the positive side, Vought had been heavily involved in trying to win new business in several different areas; two of them involving the F8U fighter. Knowing the Navy needed a replacement for the Douglas A-4 they proposed converting the F8U into a powerful light attack bomber. Vought also submitted a comprehensive F8U upgrade package to improve its effectiveness in the Fleet.

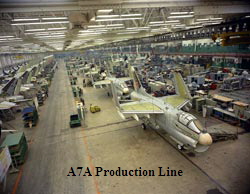

Unlike many other prime contractors, Vought always did selective subcontract work in order to increase the sales base and lower the overall manufacturing overhead. During this time frame Boeing Aircraft Company was involved in getting other major contractors to share the financial burden on their new 747 aircraft venture. Considering the urgent need for new business, Vought agreed to become a partner in this endeavor by: helping with partial funding and committing to build 201 Aircraft Aft Sections, starting in 1966, under a challenging fixed price contract. To fulfill these contracts, about 10,000 skilled workers would be required in the next four years. Training so many people in a short time span often resulted in inexperienced people having to be utilized before being adequately trained. As a result of the previous downsizing it became obvious that Manufacturing Management was not properly organized to control three major programs. Among other things, a situation existed wherein no one beneath the Vice President of Manufacturing was held accountable for a program. As a result more people had to be hired than were required in order to compensate for the lack of efficient operations. (Chart 1 C). The A7A and A7B got off to a good start because all the experienced people available were assigned to that program. However, the incorporation of an entirely new state-of-the-art weapons delivery system on the later Air Force A7Ds and the Navy A7Es created havoc in the ongoing production line before system specifications were agreed upon. Constant changes disrupted all departments. In addition, new avionics suppliers had problems of their own and their late deliveries added to the overall impasse.

The Boeing 747 aircraft program (Figure 8) was the major concern. The size of the components to be produced introduced Vought to a totally new set of requirements with which there was no experience. Larger fixturing, massive fastener installations, and the need for large material handling fixtures further compounded preparations for production. Space needs dictated that assembly would be at a different facility which required a longer make ready and setup time than expected. A significant problem surfaced when it was determined that the large automatic riveting machines, which were purchased for this program, were found inefficient and unable to do the task expected. Since fastener installation is the primary cost driver it was obvious that major machine changes were necessary or the price committed to Boeing would be considerably overrun. Consequently, at the beginning of 1969 the LTV Corporation was faced with a critical situation that was severely impacting their expected sales and reputation. All programs were late to schedule and considerably over their cost targets. The prime A7 program was 26 airplanes behind schedule. The Navy was greatly concerned that their best fighter, the F8U, which was desperately needed in the Pacific Fleet, was 60 airplanes behind modification delivery commitments. Finally, a frustrated Boeing organization was preparing to move the entire 747 contract back to Seattle and charge Vought for all overruns. Transition: Serious Vought Problems, 1958 - 1969 Major Actions Taken by Vought, 1969 - 1971 Beating the Competition Into the 1980’s and Beyond.

|

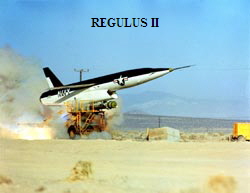

In late 1958 business at Vought Aircraft was seriously impacted by the termination of two major contracts: the F8U-3 Fighter aircraft, and the Regulus II Missile. As a consequence, shop manpower dropped immediately from 7,600 to 4,800 people (

In late 1958 business at Vought Aircraft was seriously impacted by the termination of two major contracts: the F8U-3 Fighter aircraft, and the Regulus II Missile. As a consequence, shop manpower dropped immediately from 7,600 to 4,800 people ( Without

Without Vought won two proposals.

Vought won two proposals.

The F8U Modification had a bad start, mainly due to the need for using untrained workers, also many of the supervisors were not familiar with the basic F8U airplane. Adopting to the concept of remanufacturing, which requires a different approach from that of building new aircraft, added to the completion’s being late.

The F8U Modification had a bad start, mainly due to the need for using untrained workers, also many of the supervisors were not familiar with the basic F8U airplane. Adopting to the concept of remanufacturing, which requires a different approach from that of building new aircraft, added to the completion’s being late.